Earth Moving Modes of Operation

Tractor pulled scrapers come in many shapes and forms. They can also be used in different ways. During a normal project it is likely that there will be different work phases. For instance, most projects will involve at least one of the following phases:

- Performing bulk hauls to quickly move the largest areas of deepest cut to the largest fill areas.

- Dragging shallow cuts to adjacent shallow fill areas.

- Finishing/Brushing/Grading/Trimming.

There are many variants on these basic phases and certain operators will have their own additional phases, suitable for their specific purposes.

While there will be overlap between the listed phases, they can be distinguished based on three primary factors

- Carry vs Drag

- Carry: dirt is loaded into the scraper bowl and then carried (hauled) to the destination, vs

- Drag: the blade remains on the ground and dirt is pushed/dragged along from cut to fill area

- Variable direction vs uniform pattern

- The direction of passes in carry operations tend to be determined by the relative locations of the major cuts and fill areas. Individual haul runs can be in any direction.

- Trimming operations normally consist of uniform, parallel travel paths. GPS guidance is often used.

- Drag operations can be a mixture of both pattern and variable paths. This depends on the characteristics (shape, size, location) of the cuts and fills.

- Implement type (Elevating bowl vs Drag blade)

- A drag blade can be an efficient tool for finishing, and for drag phases

- A "bucket" or "scoop" type scraper (usually with an apron, and tipping bowl or ejection mechanism) is more efficient for 'cut & carry' type operations - such as performing bulk hauls.

The different phases require different approaches to estimating expenses. In general, there will be differences in:

- Average speed of operation

- Distance travelled

- Average engine load, and fuel use.

- Time taken.

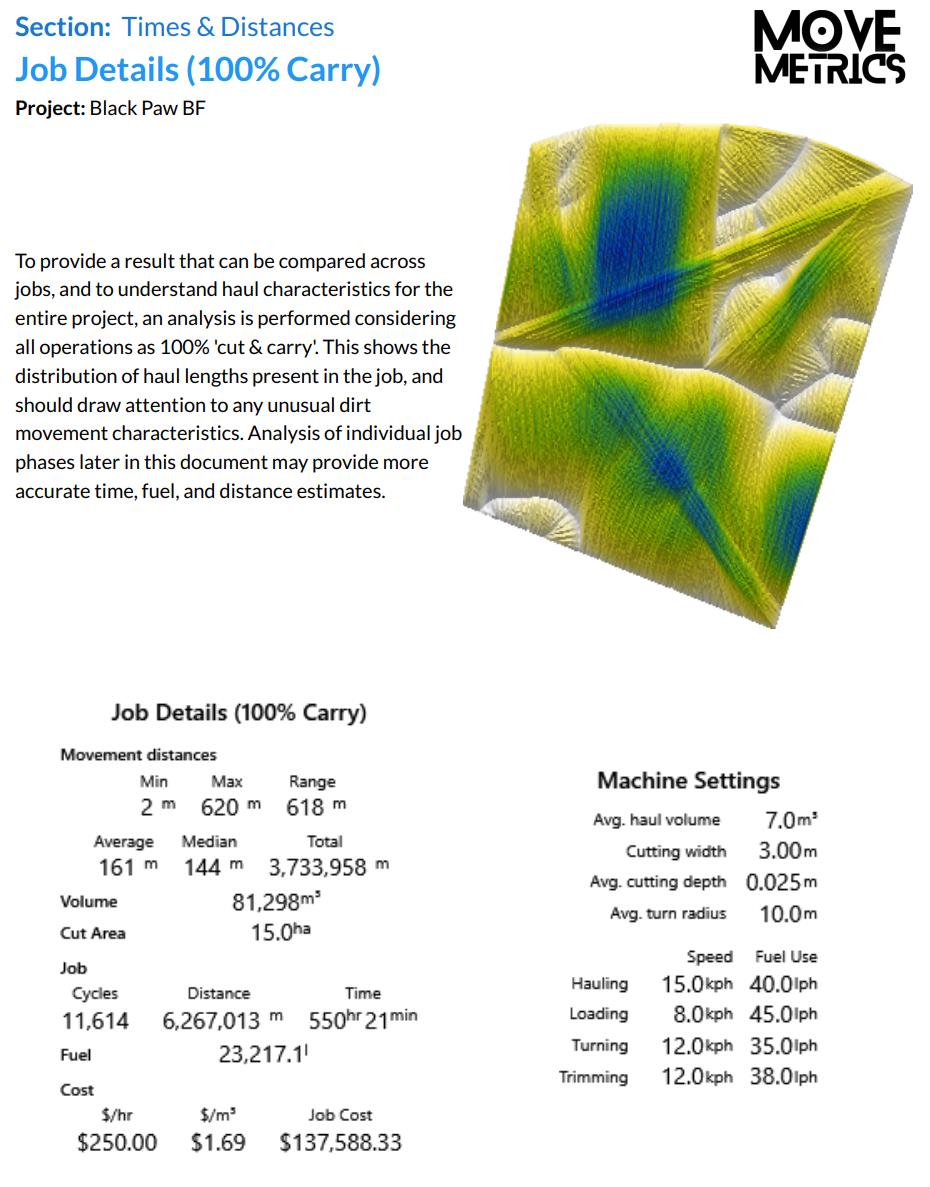

Haul Overview

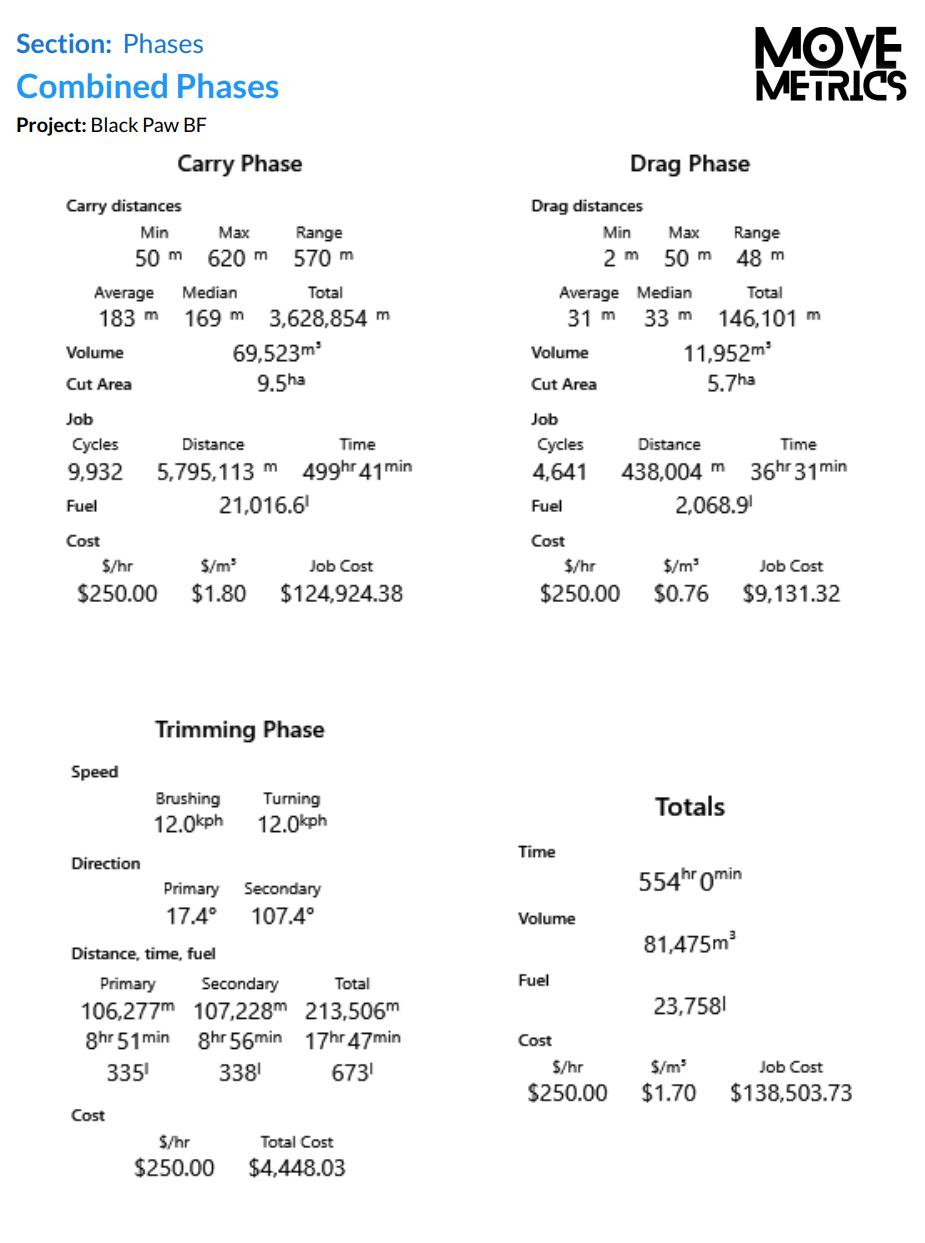

To calculate the most accurate time, fuel, and cycle distance estimates it makes sense to divide a job into individual work phases.

However, in order to provide a uniform analysis that can be compared across jobs it can be useful to analyze the entire job using a single operational phase.

Move Metrics chooses to utilize the 'Carry' phase of operations for this purpose.

Doing this shows the distribution of haul lengths present in the whole job, and should draw attention to any unusual dirt movement characteristics. Analysis of individual job phases may provide more accurate time, fuel, and cycle distance estimates.

A Move Metrics report also considers the job taking into account different modes.

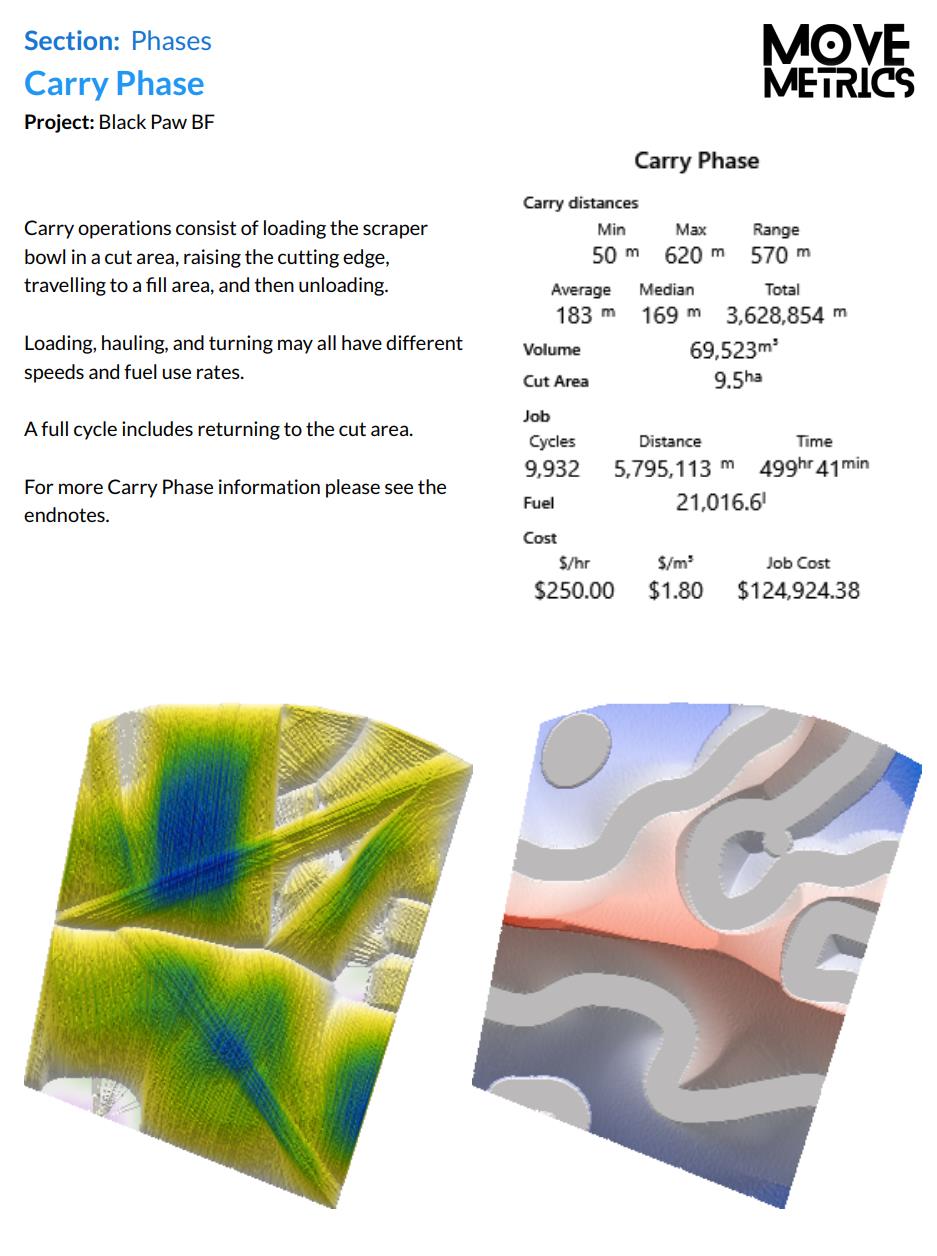

Carry Phase

Carry cycles are considered to consist of the following operations:

- Loading (in cut areas)

- Hauling (from cut areas to fill areas)

- Unloading (in fill areas)

- Turning

- Returning (fill areas to cut areas)

Each of these operations may be best performed at different engine and ground speeds. This contributes to different fuel burn rates. The time taken for each of these operations will depend on the speed as well as the distance covered during the phase. The distance required in each phase is determined by:

- Loading: cut depth, cut width, and bowl capacity

- Hauling/Returning: distance between cut and fill areas.

- Turning: machine turn radius

The cut depth is determined by machine characteristics (the depth to which a certain implement/tractor combination can realistically cut), ground characteristics (the resistance of the soil to penetration), and the design (the depth of cut required).

Bowl capacity is a function of the implement, however in certain soil conditions it may not be possible/optimal to fully load the bowl. It is assumed that each cycle loads to the capacity of the scraper bowl (which may not be possible/optimal depending on soil and soil moisture conditions). In certain conditions it will be necessary to alter the specified bowl size to more accurately represent the volume of soil carried in each cycle.

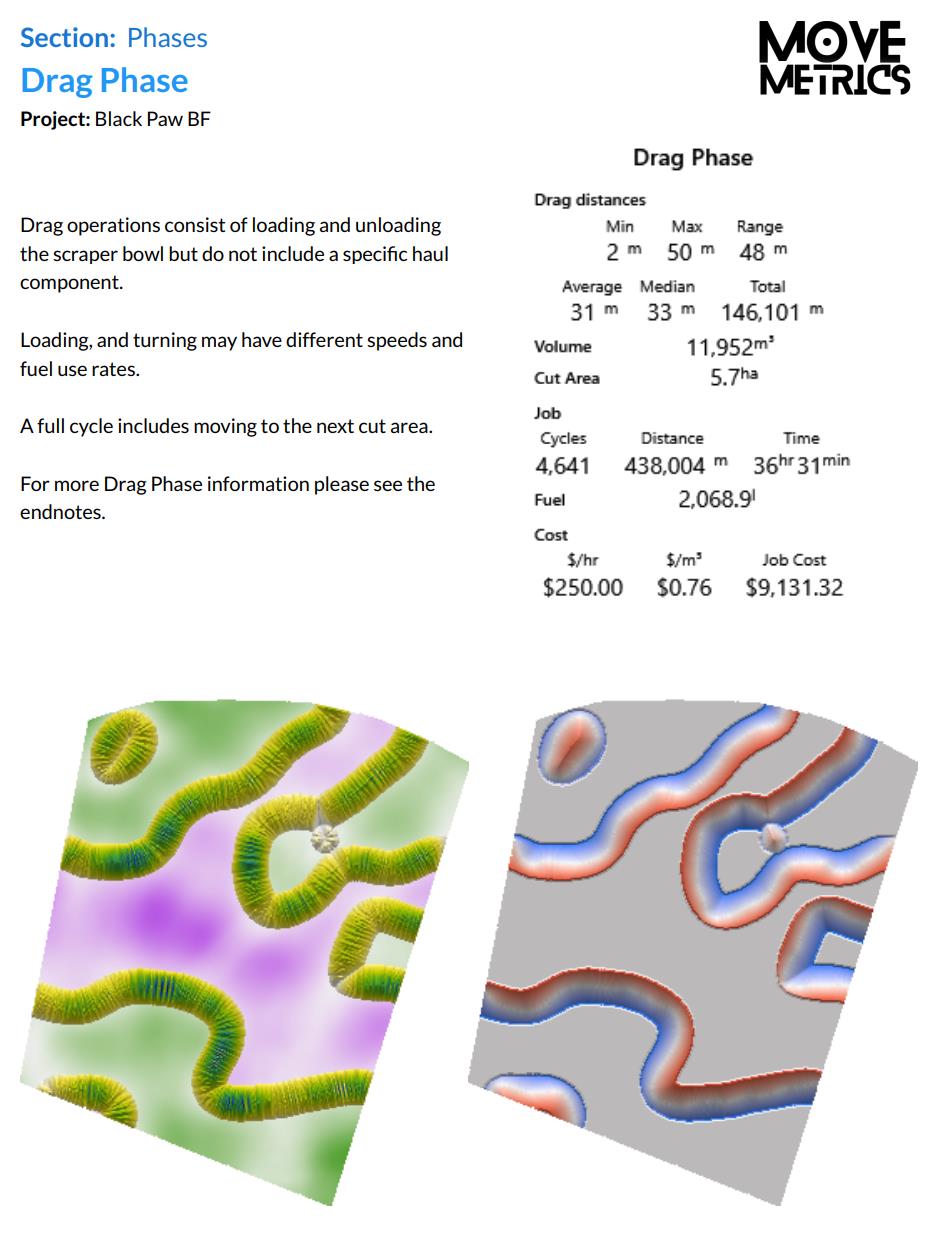

Drag Phase

The distinguishing characteristic of Drag cycles include:

- they are not considered to require full capacity for each cycle

- they are considered to have a maximum haul distance.

- they are not considered to have a significant loading/unloading period (as this is built in to the haul phase)

The max distance for drag operations is determined by a balance between scraper load volume, and time spent loading. As many drag operations will be sequences of quick cuts and fills it may be more efficient to drag an amount of dirt from a cut to a fill even if the bowl is not full, rather than to turn and finish filling the bowl prior to travelling to the fill area. Beyond a certain distance it will be more efficient to spend the time fully filling the bowl prior to hauling. Even though a maximum distance can be specified, it is worth noting that this distance may be too far in one situation.

That happens when a drag begins in the direction of a fill, but the bowl fills before reaching the fill area. In this case it is considered beneficial to lift the bowl and travel to the fill area. In this situation the cycle is is considered to be part of the Carry phase.

Trimming Phase

Trimming operations are not considered to have a volume associated with them.

This is because all significant volume movement is considered to have taken place during the the Carry and/or Drag phases. Accordingly, the cost of the finishing operation is considered to be determined by the distance required (including turns) to cover the entire field.

After showing the results for individual phases, the report combines them all.

Factors that are not currently taken into account:

- Haul roads

- Impassable field areas.

- Stockpiling (unless the stock pile is built into the design)

- Topsoil removal and replacement (unless this phase is performed as a separate control map)

🚜🚜🚜